Traditional refrigeration plants are often dubbed "energy black holes" due to their high energy consumption, low efficiency, simplistic maintenance, and lack of space for equipment upgrades. Particularly under the "Dual Carbon" goals initiative, enterprises urgently need solutions that can dramatically reduce carbon emissions while enabling rapid deployment.

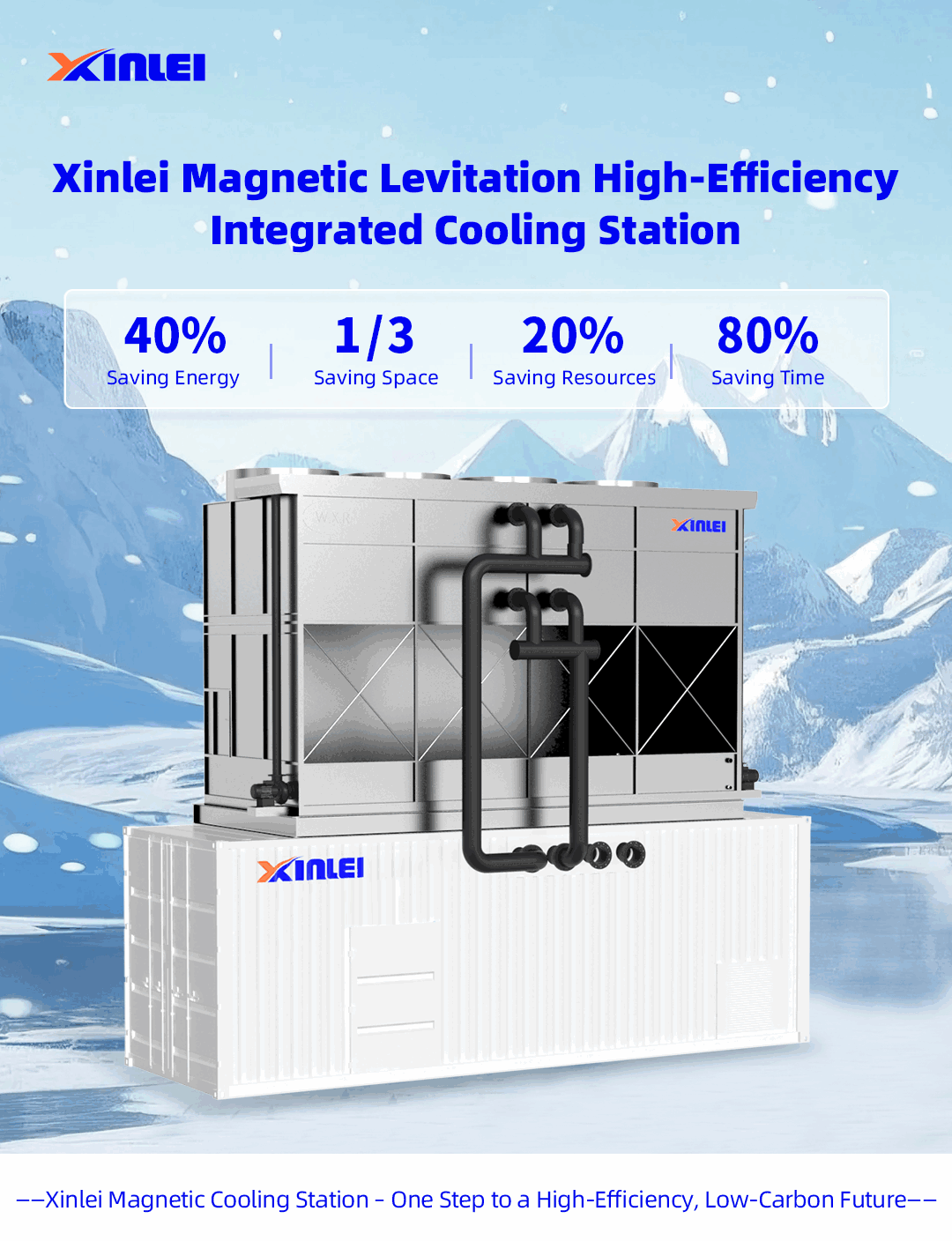

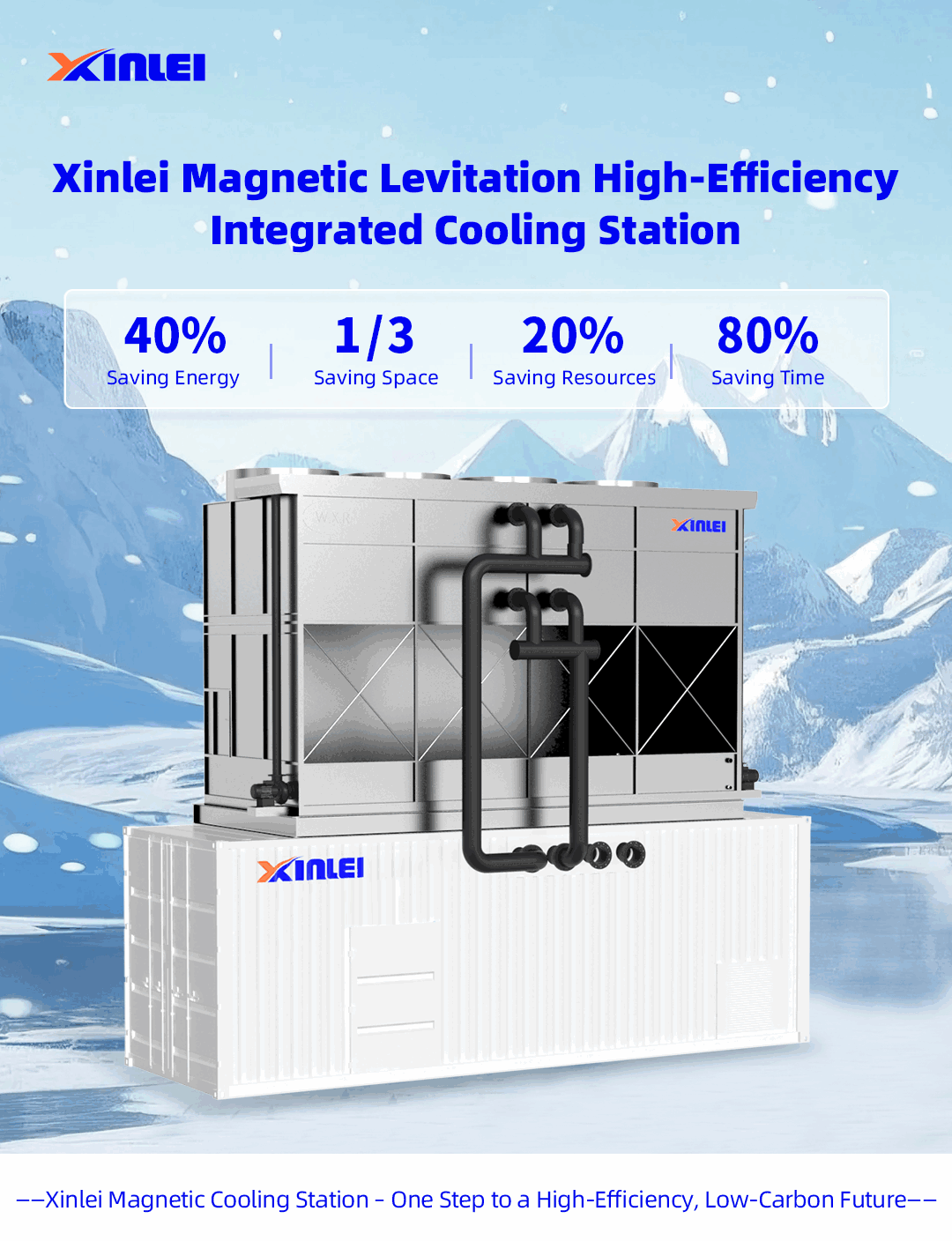

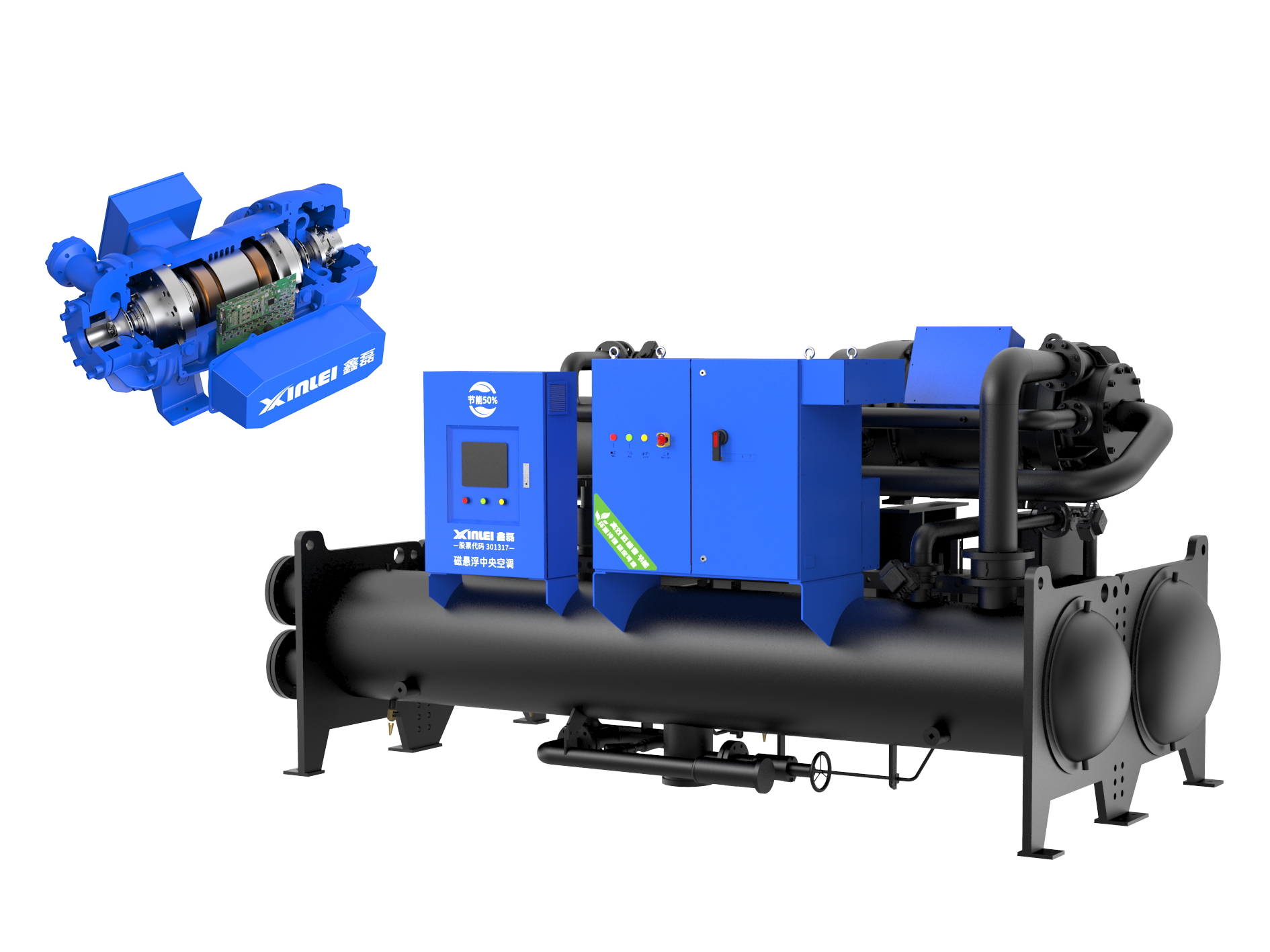

Xinlei's Maglev High-Efficiency Integrated Cooling Station arrives as a timely solution, delivering complete chain innovation that achieves immediate energy conservation and consumption reduction. This breakthrough provides sustainable cooling energy support for industrial, commercial, and specialized applications.

Compact footprint with flexible configuration

Integrated design revolutionizes conventional construction practices

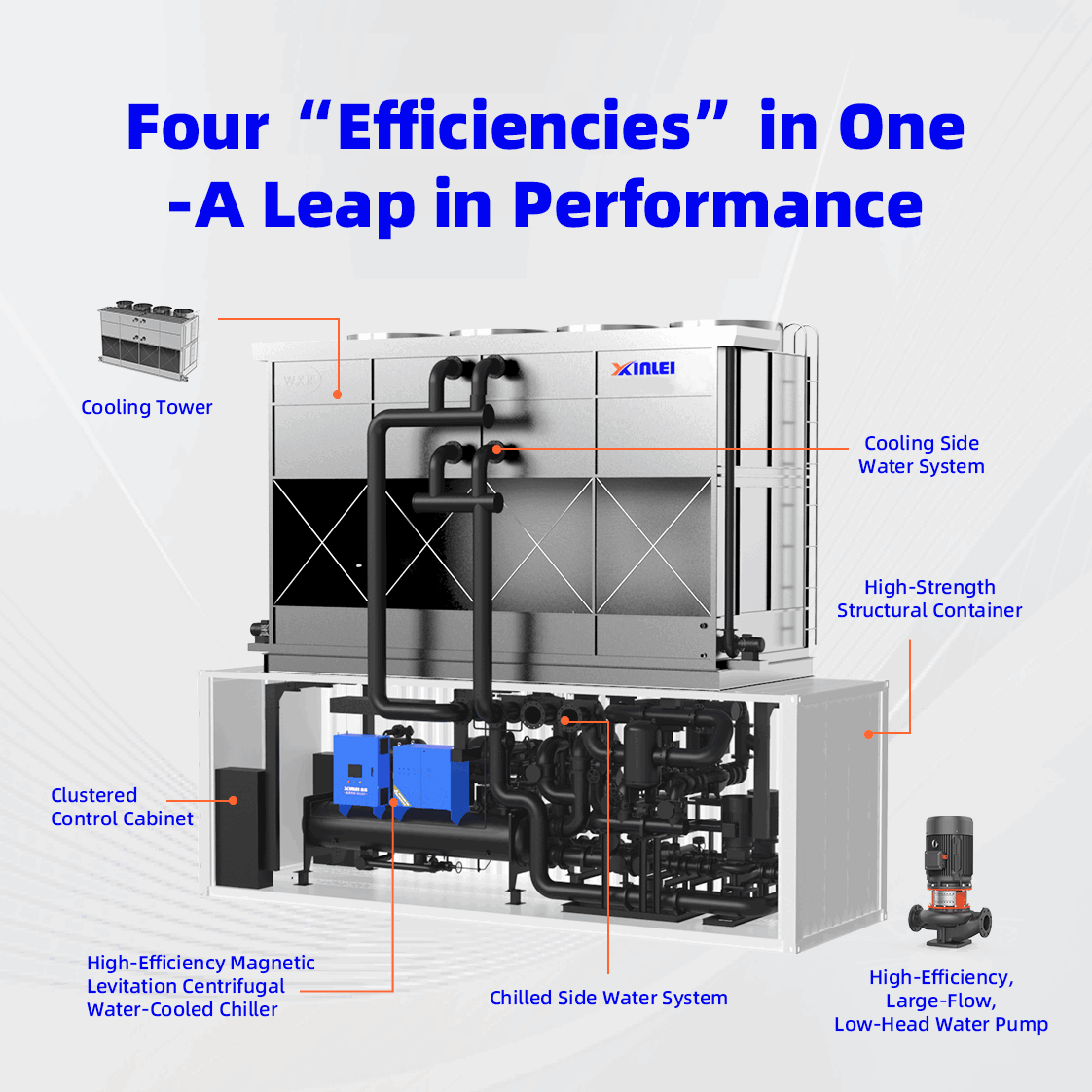

Xinlei Maglev Centrifugal High-Efficiency Integrated Cooling Station =Magnetic Levitation Centrifugal Water-Cooled Chiller Unit+High-Strength Structural Container+Cooling Water System (Condenser Side)+Chilled Water System (Evaporator Side)+Cluster Control Cabinet+Cooling Tower**

Featuring a high-strength modular containerized design, the system can be installed outdoors or on rooftops. The cooling tower is mounted atop the container, with water systems arranged vertically across upper and lower levels. This configuration requires only 1/3 of the footprint of traditional engine rooms, while maintaining full compatibility with existing building systems to minimize structural modification impacts.

Energy-saving with superior cost-efficiency

Maglev Centrifugal Chiller Unit (Exceeding Tier-1 Energy Efficiency, 50%+ Energy Savings)

Equipped with proprietary dual Tier-1 efficiency maglev centrifugal compressors, featuring optimized aerodynamic design for enhanced operational performance:

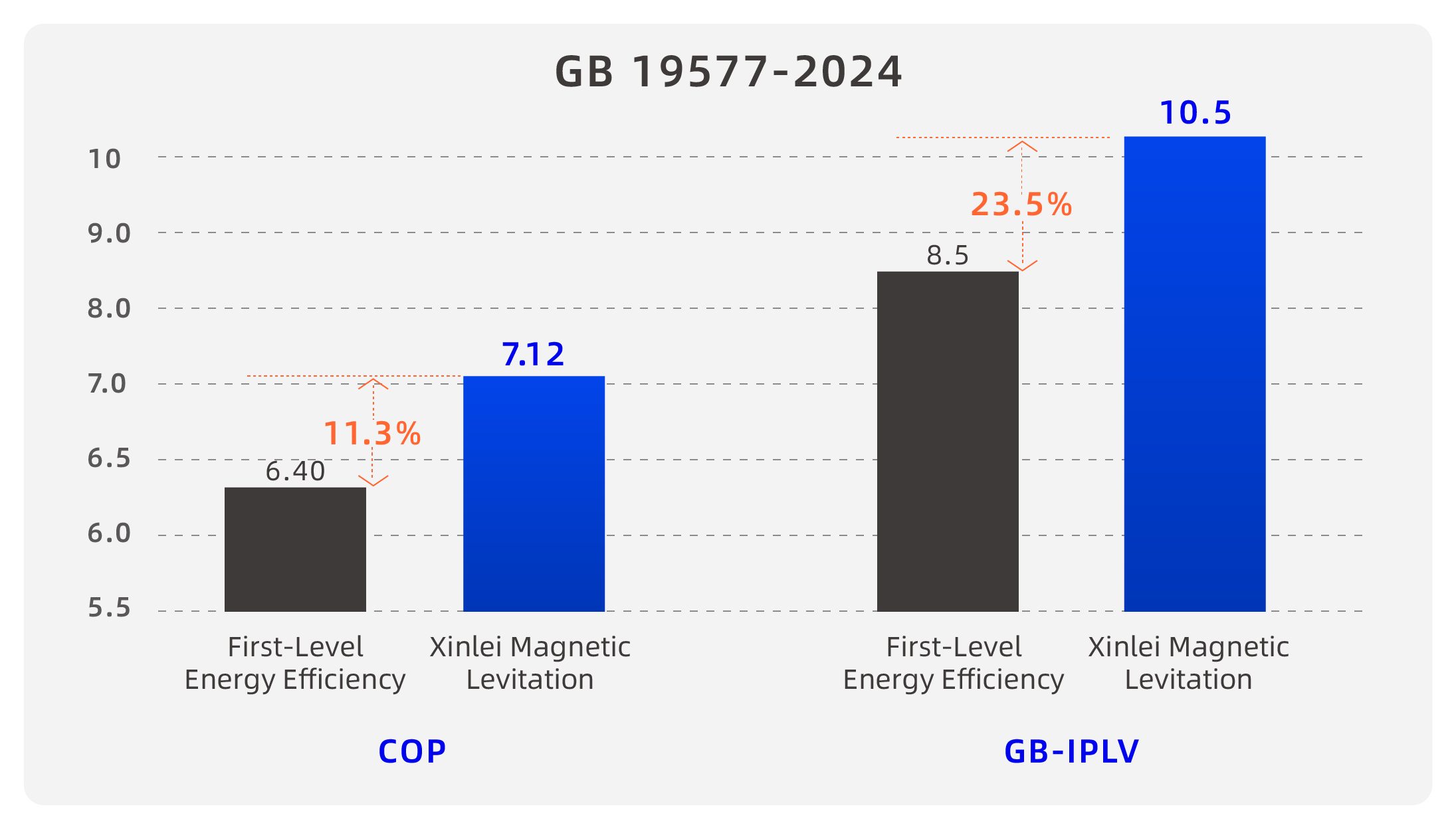

Full product line delivers cooling COP up to 7.12

12% above China National Tier-1 efficiency standard

IPLV rating reaches 10.5 across all models

26% beyond Tier-1 requirement

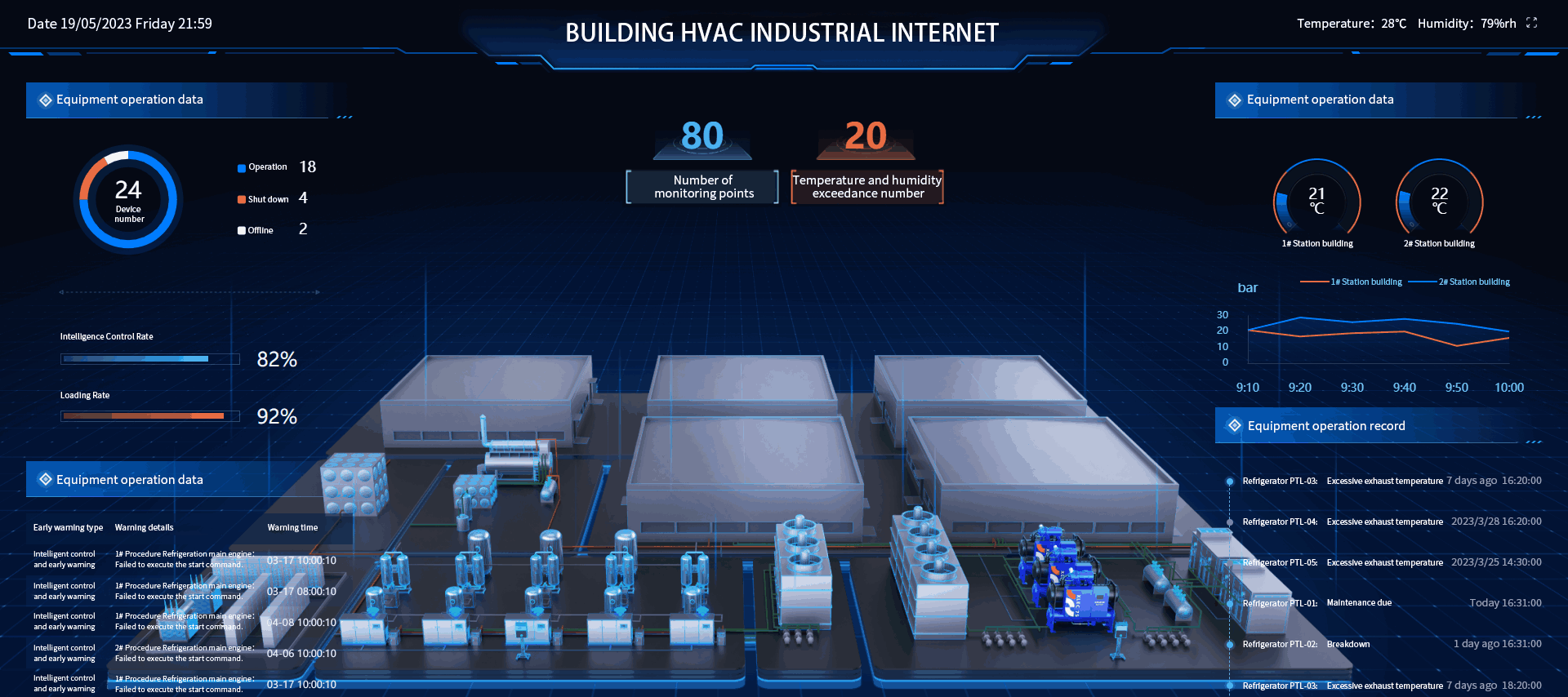

Energy Efficiency Made Intelligent

AI-Powered Control | Dynamic Demand Response

◆Chiller Smart Control丨10%-100% ultra-wide load modulation

◆Hydronic-Air System Intelligence丨Dual-engine operation:Dynamic temperature regulation Differential pressure bypass control

◆Triple Integration System丨Unified platform combining:Intelligent control systems,Building Automation System (BAS),Smart low-voltage distribution,Annual electricity cost savings: ≥30% above industry benchmark

*(Standards Alignment:

The system features built-in proprietary AI algorithms that monitor building load fluctuations in real-time and dynamically adjust water flow and temperature. For instance, under partial load conditions, it automatically reduces compressor speed and pump frequency to prevent energy waste from "oversized capacity operation," achieving optimal energy efficiency. Additionally, it supports cloud-based remote management and predictive maintenance, reducing the need for manual inspections and improving operational efficiency.

The system monitors end-user load fluctuations in real-time and, with the host unit at its core, dynamically coordinates the operation of pumps, cooling towers, and other equipment through PID-based fuzzy control to deliver precise output on demand. Compared to conventional methods, this approach reduces energy consumption by 20%–40%, achieving an integrated part-load value (IPLV) of up to 7.55 for the entire cooling plant.

Time-Saving & Ultra-Efficient

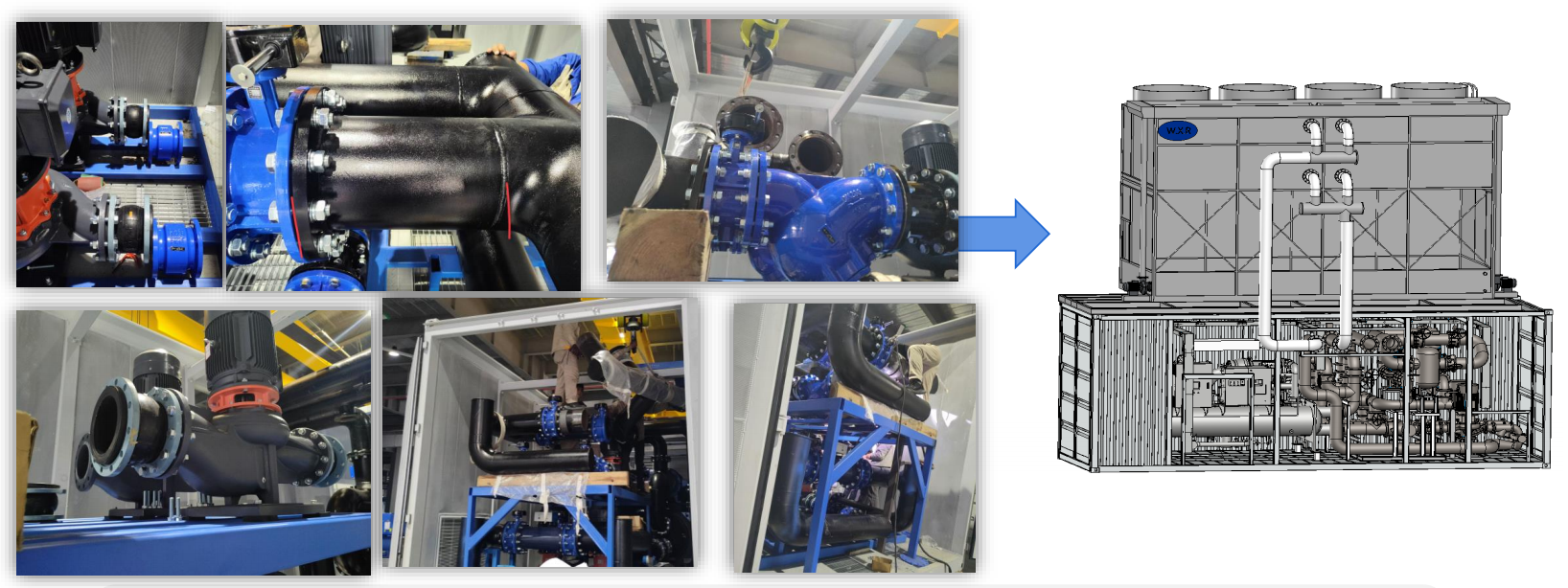

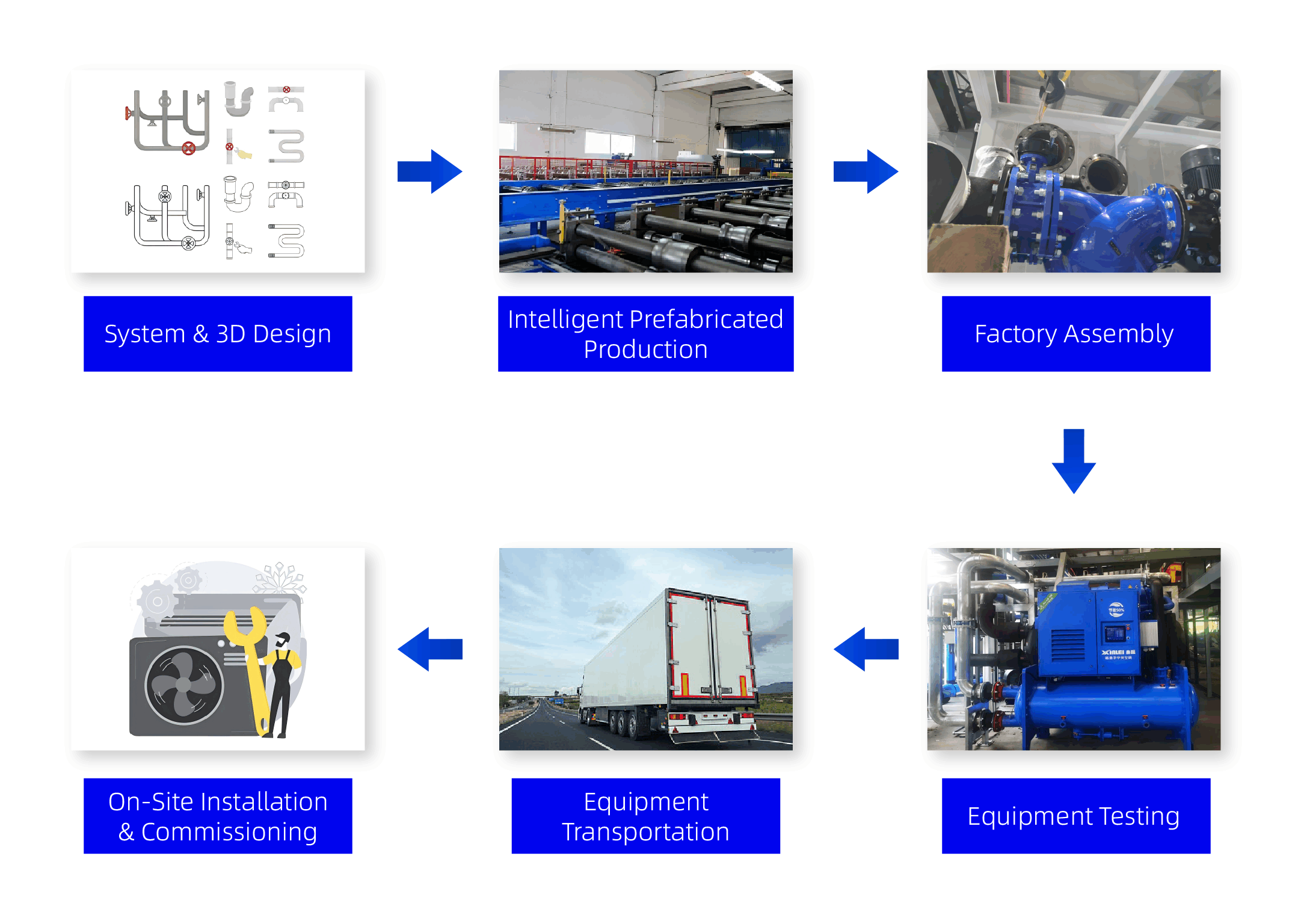

By innovatively applying 3D modeling technology, the system enables fully digitalized design of the entire pipeline network—optimizing spatial layout and maintenance workflows to streamline installation, operation, and servicing. Meticulously engineered, this smart integrated cooling plant solution delivers minimized footprint, superior operational ease, and maximized maintenance efficiency.

Leveraging precision 3D design blueprints, the system adopts an integrated embedded design with 90% prefabrication rate—enabling true plug-and-play deployment. Simply connect water and power supplies for immediate operation, reducing on-site installation time by 80%. Ideal for retrofit projects with tight schedules.

Xinlei Magnetic Levitation High-Efficiency Integrated Cooling Station can be widely applied in various types of buildings, optimizing energy allocation and operational strategies to reduce energy consumption and carbon emissions:

Public Buildings

Large-scale venues such as commercial complexes, hospitals, and transportation hubs—enhancing energy efficiency and supporting green certifications.

Industrial Applications

Data centers (low PUE),Biopharmaceuticals (cleanroom temperature control),Precision manufacturing (constant temp & humidity)

Specialized Scenarios

Scientific cryogenic labs,Cold chain logistics,Military facilities (extreme climate control)

Retrofit Upgrades

Modular replacement of legacy cooling systems without structural modifications, slashing project timelines.

Renewable Energy Integration

Compatible with solar PV, energy storage, and multi-energy hybrid systems, enabling grid-friendly flexible operation.

With outstanding engineering performance, this project was awarded the "Equipment Star" prize at the 5th National Prefabricated Electromechanical Engineering Design & Application Competition, demonstrating its commitment to delivering cutting-edge equipment and solutions for the refrigeration industry.

With the global surge in demand for sustainable technologies, Xinlei has continued to deepen its R&D efforts, focusing on adaptability to extreme operating conditions and the integration of multi-energy complementary systems. The Xinlei Magnetic Levitation Highly Integrated Cooling Station embodies the concept of "full lifecycle service," covering the entire process from design and deployment to operation and maintenance, delivering a one-stop low-carbon solution. It not only breaks through the energy efficiency limitations of traditional equipment rooms but also redefines the new standard for "high-efficiency cooling" with its "all-in-one" integration capability, accelerating the green and intelligent transformation of the construction and industrial sectors.

Choose Xinlei—Not Just for Energy Savings

But for the Wisdom to Embrace a Sustainable Future

上一篇

上一篇 Back to list

Back to list