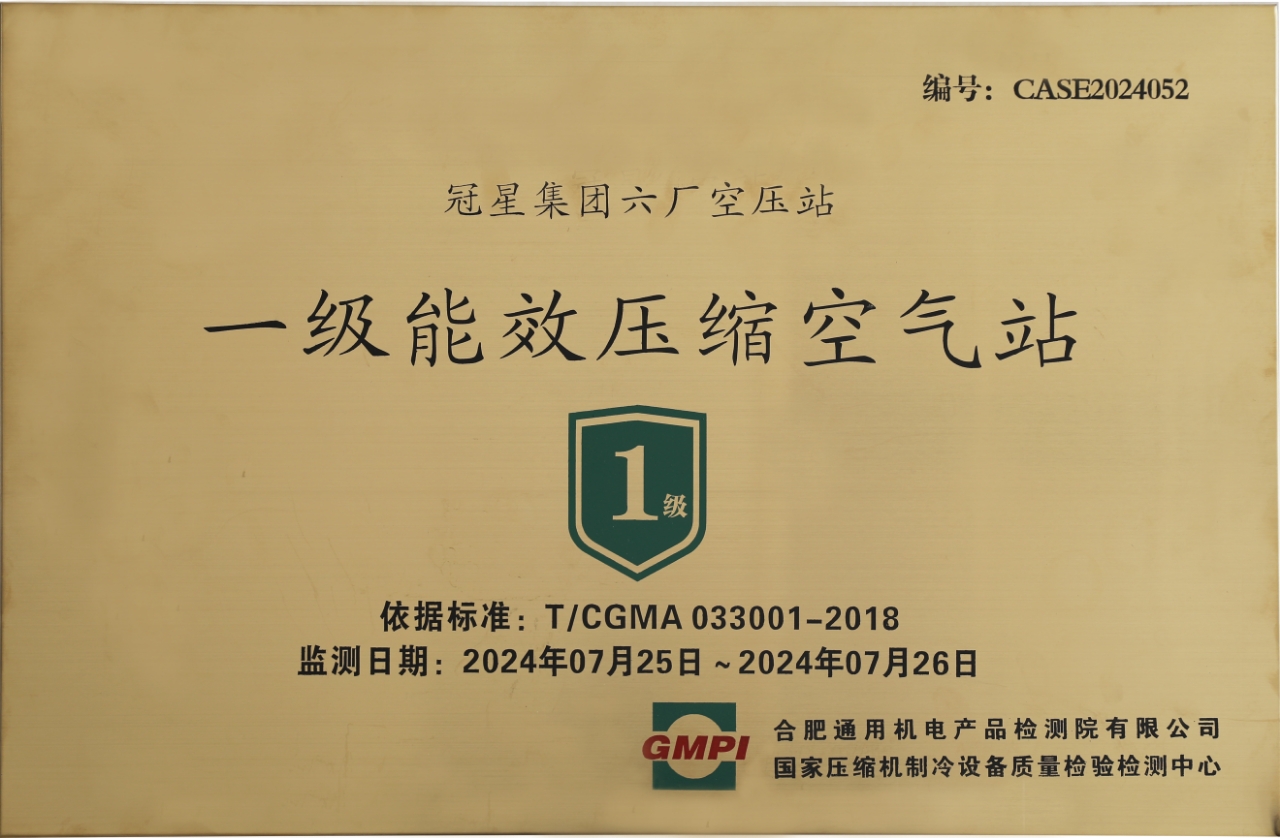

Recently, Xinlei Shares and Guanxing Group jointly completed the挂牌 (launch) of a Top-Tier Energy-Efficient Compressed Air Station. The energy-saving solution, designed and planned by Xinlei, has injected new momentum into Guanxing Group with its outstanding performance, supporting the company in reducing energy consumption, cutting costs, and improving efficiency.

Green Production: Breaking Through Energy-Saving Bottlenecks

According to preliminary observations by Xinlei’s pre-sales technical team:

· Equipment failures with unidentified causes lead to prolonged downtime and high maintenance costs.

·Mismatched air supply and demand due to fluctuating production needs, causing frequent compressor loading/unloading.

· Poor management of post-treatment equipment, resulting in unstable air quality.

These issues are the primary causes of energy inefficiency.

Guanxing Group has consistently adhered to the strategy of "innovation-driven development and green growth", actively promoting a production model that integrates intelligent manufacturing with environmental protection and energy efficiency. However, increasing production volumes have led to significant growth in electricity consumption. To establish a truly green factory, implementing energy-saving and consumption-reduction measures has become imperative.

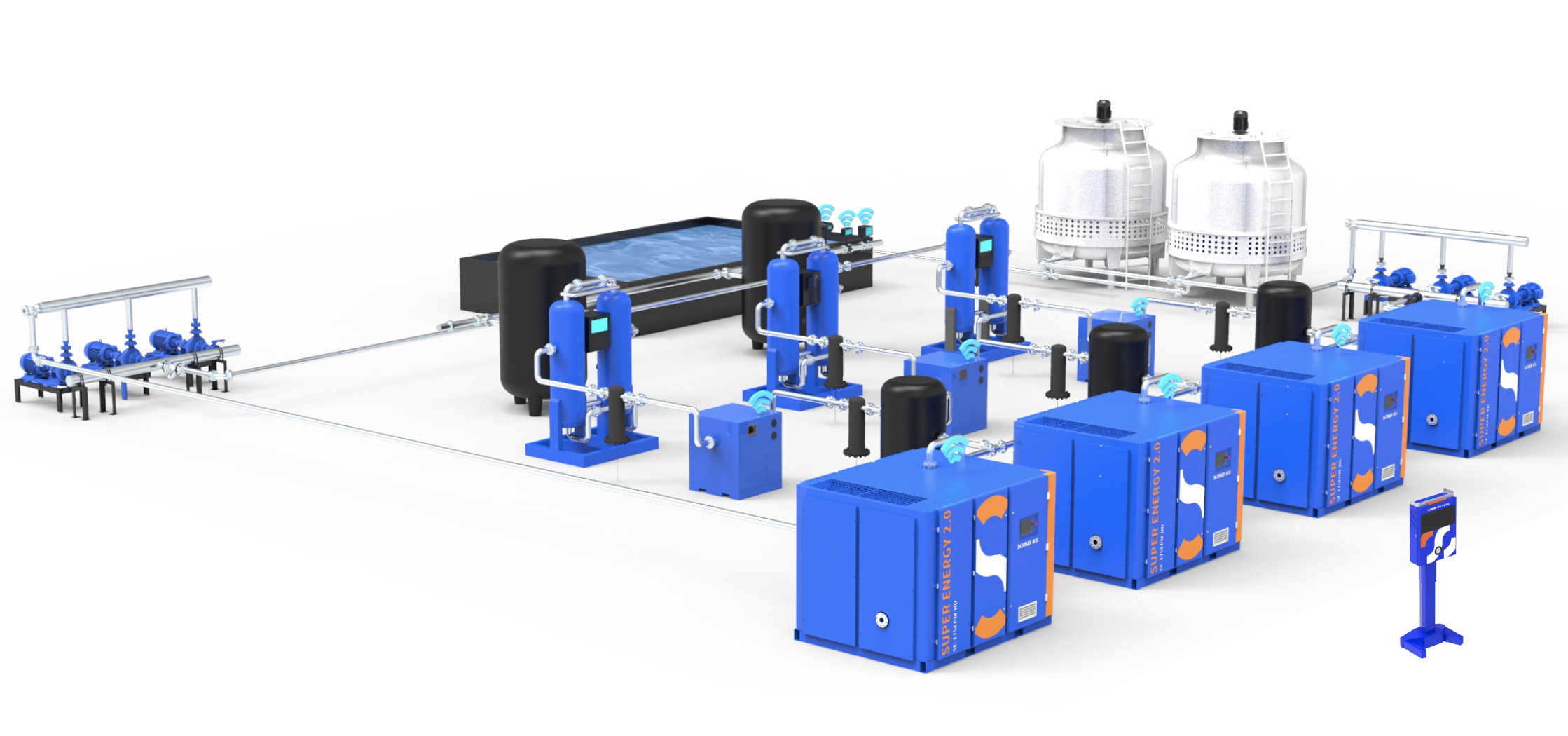

For this compressed air station upgrade project, energy management implementation included replacing original imported air compressors with 9 Xinlei Shares two-stage permanent magnet variable frequency air compressors for the spinning high-pressure air system, supplied by Qingdao Tainenda Electromechanical Equipment Co., Ltd.

Double Boost: Tier-1 Energy Efficiency + AI Algorithm

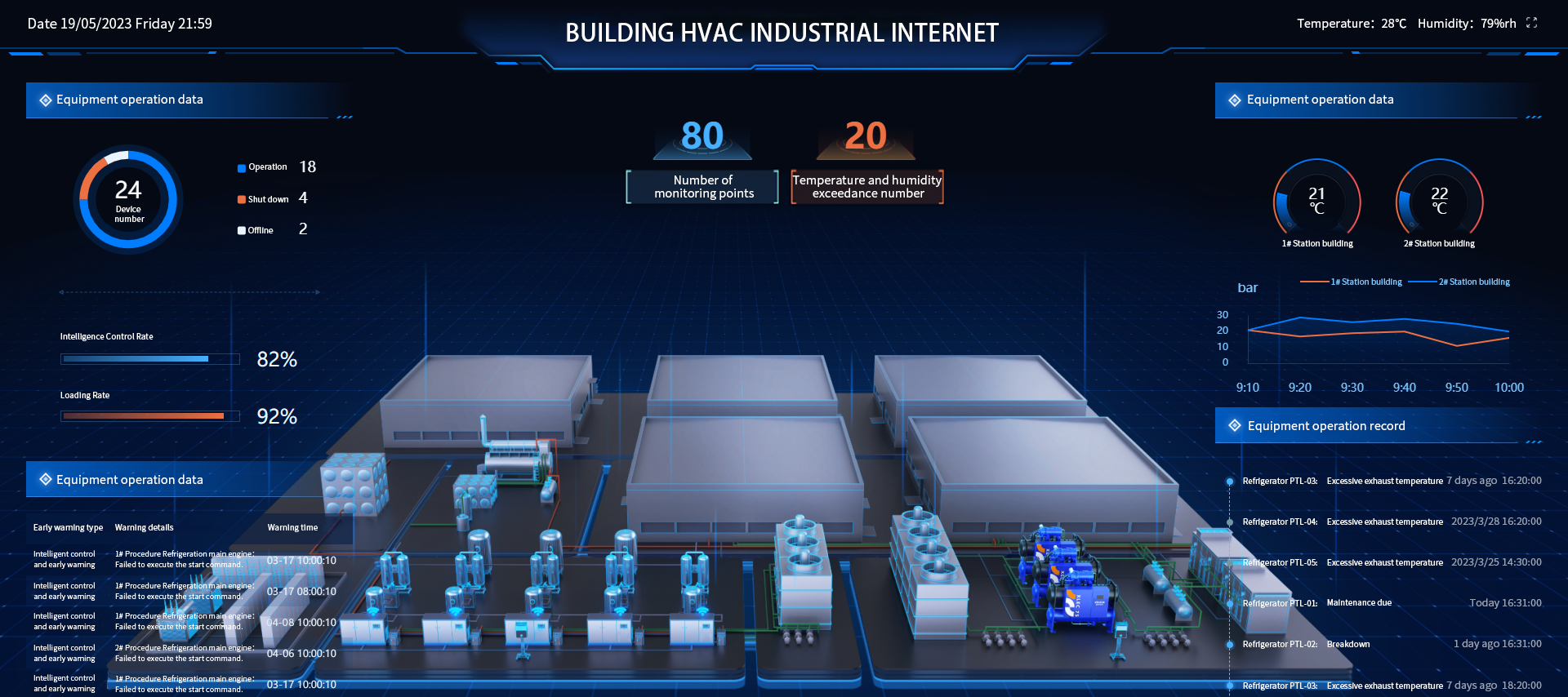

Building on its Class-1 energy-efficient equipment, Xinlei Shares integrates AI algorithms that actively monitor main pipeline pressure fluctuations. The system intelligently controls equipment start-stop sequences and dynamically adjusts operational parameters to ensure stable air supply. This solution delivers three key benefits: secure station energy supply, unmanned operation, and significant energy savings.

Genuine Beyond-Class-1 Energy Efficiency

As the core equipment of this upgrade, the Xinlei Two-stage Dual Permanent Magnet Variable Frequency Air Compressor genuinely achieves ultra-first-level energy efficiency. It adopts two-stage compression technology, performing staged compression with a compression ratio of 3, reducing backflow leakage and thereby improving energy efficiency. Its intelligent regulation function allows flexible adjustment of the compressor's output based on actual production load, avoiding unnecessary energy waste.

By monitoring the entire air compressor station for data collection, the system performs edge server + cloud-based control ("cloud-edge dual control") of key parameters such as air pressure at the usage end. This enables real-time monitoring of equipment status and air consumption matching, ensuring stable air pressure for jet looms during high-speed operation, thereby further improving weaving efficiency and quality.

The project was officially put into operation in July 2024. The air compressors in the new station facility all meet China's Grade 1 energy efficiency standards, and the entire station complies with the Grade 1 energy efficiency requirements for compressor stations.

The Xinlei Two-stage Dual Permanent Magnet Variable Frequency Air Compressor significantly enhances energy utilization efficiency in production processes through its stable pressure air supply and low-vibration design. It plays a crucial role in key manufacturing stages such as spinning and air-jet loom operations.

The certification of the Grade-1 energy-efficient compressed air station has not only strengthened collaboration among enterprises, distributors, and customers but also provided an additional layer of assurance for client equipment through authoritative third-party testing and certification. The successful implementation of this air compressor station upgrade project is a testament to Xinlei Co., Ltd.'s technical expertise and innovative capabilities in the industrial sector.

Moving forward, Xinlei Co., Ltd. will continue to pioneer green technology innovations in digital infrastructure, relentlessly optimizing products and solutions to drive the digital transformation and sustainable development of the air compressor industry. This commitment will inaugurate a "Xin" (new) chapter for the sector.

上一篇

上一篇 Back to list

Back to list